Facilities & Equipment

CNC Milling

Okuma M460-VE - QTY: 1

One of the most rigid VMC’s on the Market. This machine has all the bells and whistles. From 1000PSI thru-spindle coolant, Renishaw Spindle and Tool Probes, Dual Contact CAT40 Big Plus Spindle Nose, and 15,000RPM Spindle. This machine eats Super Alloys for breakfast, lunch and dinner.

Haas VF2SS - QTY: 1

Reliable, Repeatable and Easy to Operate our VF2 is equipped with a 12,000RPM Spindle and Renishaw Spindle and Tool Probes. This machine makes short order of our small run and one off parts .

Haas DT-1- QTY: 2

Super fast and Easy to Operate these machines handle most of our production aluminum and steel parts. With 2400IPM rapids, 1.6s tool changes and spindles up to 20,000RPM these machines are a blast to run.

Hurco VMX50 - QTY: 1

When it just wont fit anywhere else! This machine has travels of over 50″ in X, 26″ in Y and 26″ in Z and is equipped with a 10″ Rotary 4th Axis.

CNC Turning

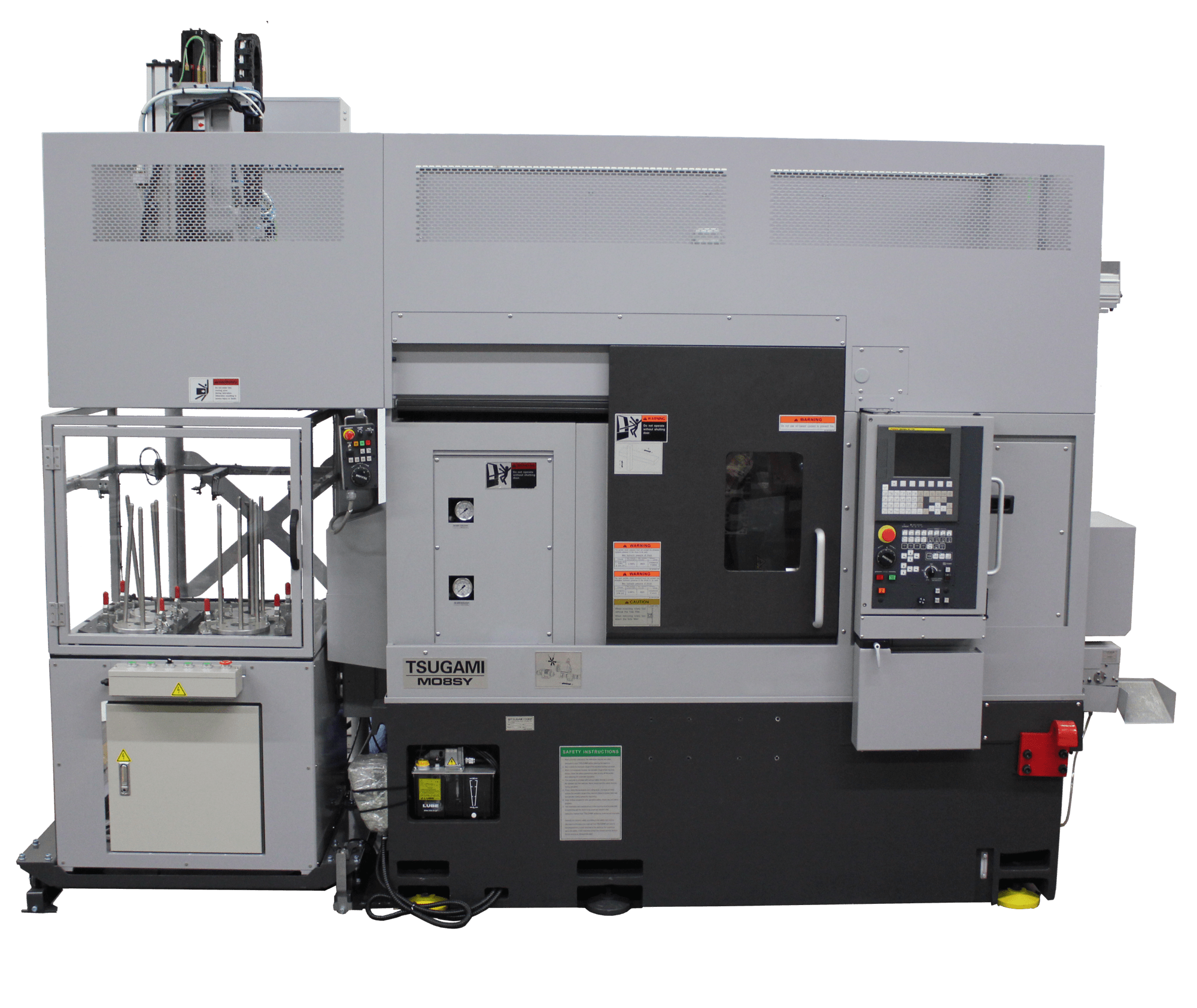

TSUGAMI MO8SY-II w/GANTRY LOADER - QTY: 1

With Live Tooling Available in Every Station, Full Y Axis, and 2 Spindles, our MO8SY-II can handle any task you can throw at it. From one off parts to high production, this machine can hold tight tolerances in the most unforgiving materials.

Hyundai Wia LV800RM - QTY: 1

Capable of turning up to 31.5″ in both length and diameter, our Vertical Turret Lathe allows us to large format turn complex parts with ease. With Live Tooling Available in Every Station, Full C Axis, an 18″ Chuck and a 32″ Fixture Plate, it’s ready for any task you can throw at it.

Kia Kit 30B - QTY: 3

These machines are the backbone of our turning department. Extremely rigid and equipped with dead length collet chucks they are extremely user friendly and versatile machines. From simple turnings to tight tolerance work and threading our Kia’s get the job done.

Nexturn SA38e Swiss Style Lathe - QTY: 1

7 Axis – Front Working, Back Working and Cross Working Live Tooling. Capable of Feeding up to 1.5″ Stock…This machine was made to make the most complex parts in ONE operation.

wire edm

Sodick VZ500L - 5 Axis Wire EDM - QTY: 1

Capable of making precision cuts through anything that conducts electricity, our Sodick VZ500L can handle parts up to 22″ Long, 16″ Wide and 9″ Tall. With some of the most advanced technology in the EDM market we are capable of holding tolerance as tight as +/- 0.0001″

welding

Miller Dynasty 200 - QTY: 2

Our Miller Dynasty 200’s are equipped to handle any welding job. With HF, Pulse, Square Wave, and fully Water Cooled they’re up to the challenge of welding Aluminum, Stainless Steel, or High Temp Alloys

BuildPRO MAX Nitrided Fixture Table - QTY: 2

We love our BuildPRO tables. Decked out with all the accessories these tables can fixture anything from simple frames to complex assemblies, all while keeping things flat, square and in spec.

Millermatic - QTY: 1

Used primarily on steel our Millermatic 251 is powerful enough to weld 1/2″ plate in a single pass. Invaluably useful for quick jobs or tacking up complex assemblies.

Welding Support Equipment

From fixture clamps to angle grinders and everything in between we have the right tools for the right job guaranteed. With everything neatly organized and at arms reach, we’re efficient and effective, completing your project with speed and accuracy.

inspection

Mitutoyo Bright Apex CMM - QTY - 1

Located in a climate controlled environment and capable of measuring large parts with extreme accuracy our Mitutoyo CMM gives peace of mind that even the most complex details are captured and recorded.

1Factory Automated Inspection Software - QTY: 1 Seat

Our 1Factory software gives us powerful inspection tools at our fingertips. Auto-ballooned drawings, easy to setup FAI’s and automated PPAP’s, 1FActory helps us ensure that your project comes out right every time.

Height Gages/Surface Plates - QTY: 3

Placed strategically throughout the facility our range of height gages and surface plates are easily available for our technicians to inspect your parts.

Inspection Support Equipment

We can’t forget the little stuff….Here at Reformed MFG our Inspction Department is fully loaded. From calipers and micrometers, to thread gages and pin gages, we have it all. Every piece of measurement equipment is calibrated and certified on a rotating schedule to NIST standards and meet all requirements of ANSI/NCSL z540-3-2006, ISO 10012-1:1992(E) and ISO/IEC 17025.

facility

Located directly of Rt. 95 in Salisbury, MA our state of the art facility is easily accessible to all major shipping and delivery routes. Our main manufacturing floor is fully climate controlled and kept immaculately clean. Daily 5s activities keep our departments in tip top order and help facilitate an enjoyable work environment.